Franklin Glassblowing Studio

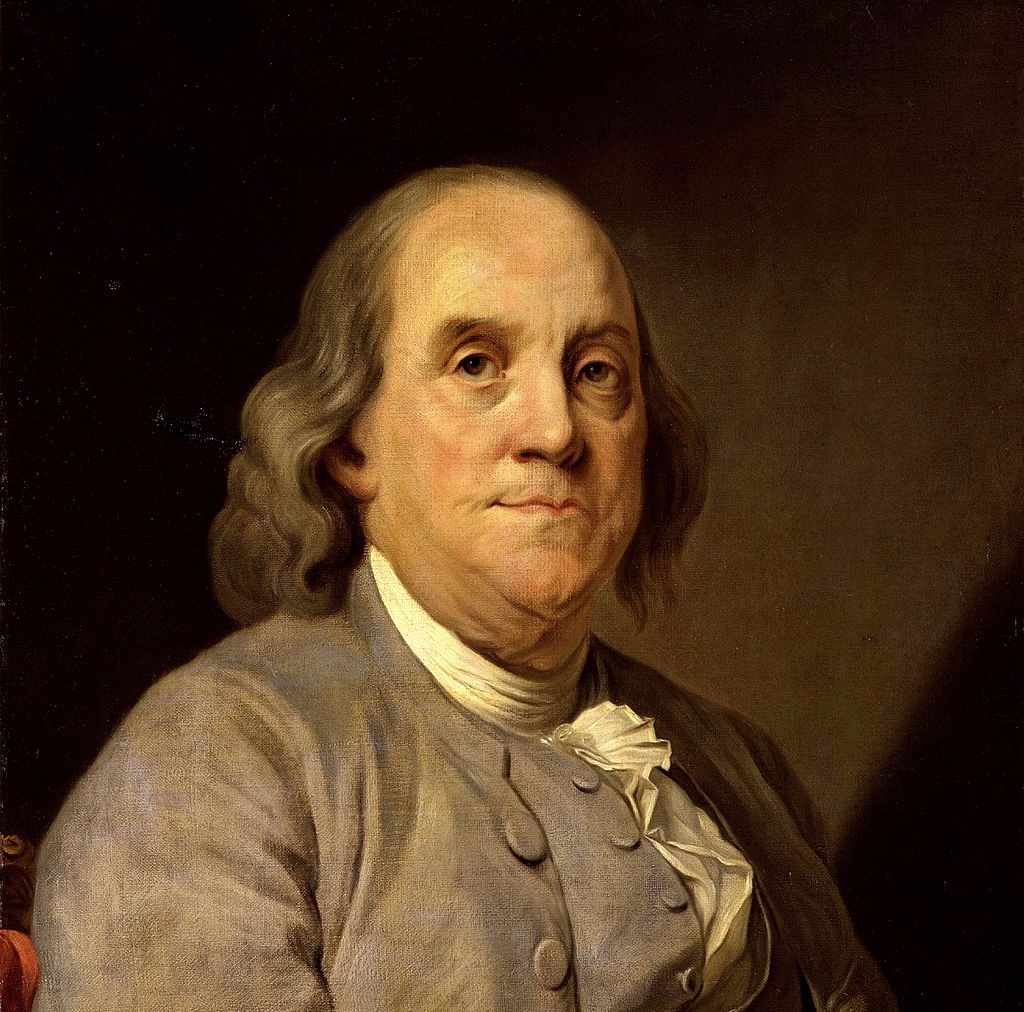

Benjamin Franklin was a well known pioneer of Philadelphia glass making. We continue that tradition today.

ABOUT US

Benjamin Franklin was a well known pioneer of Philadelphia glass making. We continue that tradition today.

The family founded the Franklin Glass Company when Benjamin Franklin took over his father's business in 1732, following the death of his uncle Joseph Franklin. Franklin was a natural and quickly became a pioneer in commercial glass and a highly successful glassmaker.

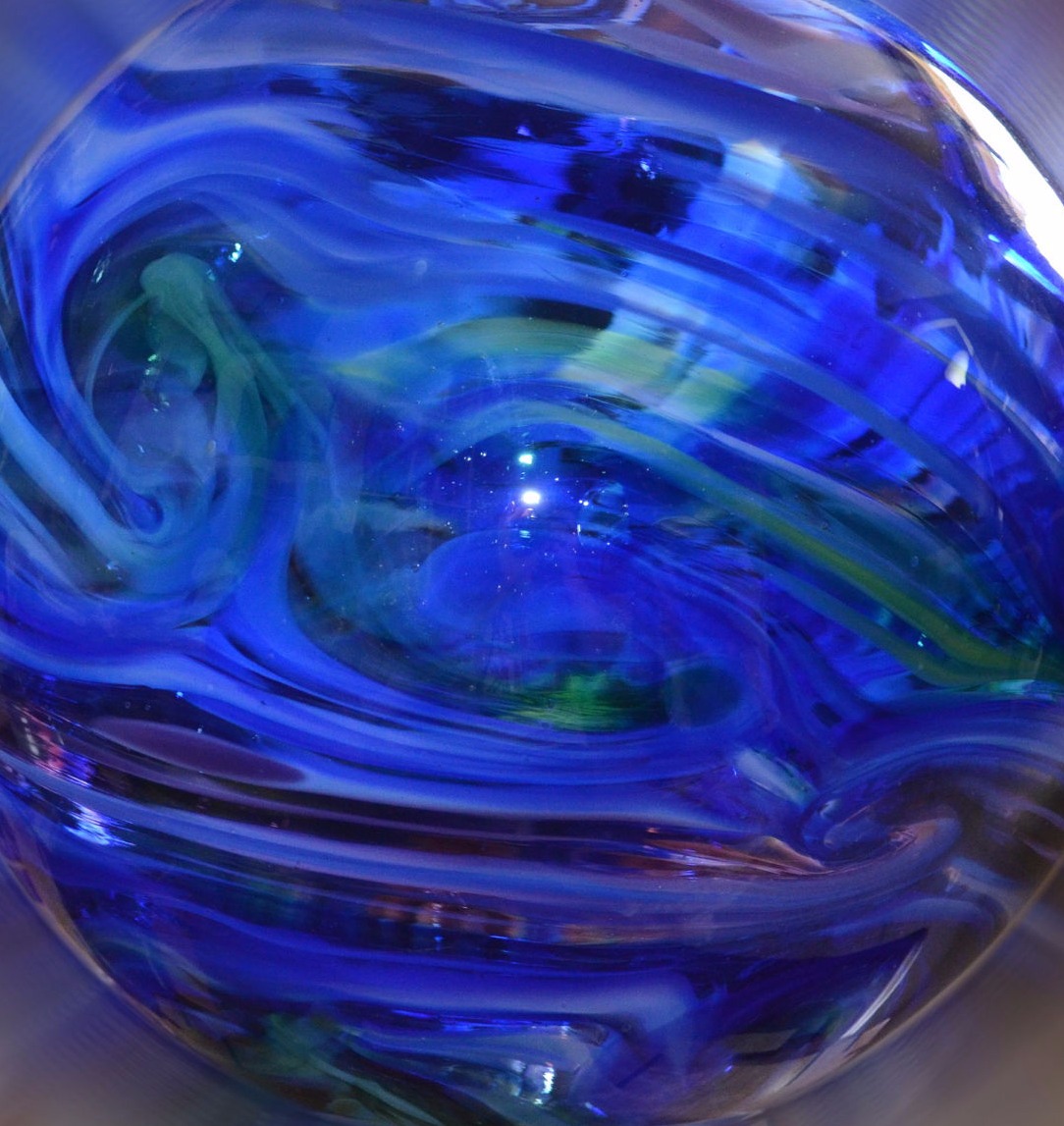

The glass used in Benjamin Franklin's factory, designed by John Thomas White, used sand imported from France. The glass was mixed with an iron pigment and then pressed and polished for use in glassblowing. This particular glass produced a nice, clear and deep shade of blue.

In 1778, Franklin Glass began producing glass for the Federal government, but their production facility was shut down when Thomas Jefferson became President of the United States. To make up for the shortage of glass, the James Madison Federalist Paper was published in 1783, calling for the production of all kinds of glass.

In 1792, the Jeffersonian movement gained strength, and business ownership by the people was considered to be an important civil liberties issue. This was particularly true of the production of glass.

In 1818, a new glass was introduced to the market by French company, DuPont. It was called 'St. Helena' or 'Moorish Silver' as its purity was considered to be "too low" for safe use by both government and industry.

Yet demand for the product increased so much that it had to be banned by the U.S. federal government and by the government of France, Belgium and the U.K.. It was then that FGbS was able to mechanize glass blowing, once inneficiently practiced by artisan craftspeople, and finally return American Made glass to the world stage at scale.

"Hand made? mouth made? Theres a picture on John in Sales' cubicle wall of someone blowing up a glass baloon at the end of a big metal straw or something. Apparently that is how it used to be made? Now it's mostly machines and outsourced foreigners with lax environmental regulations and child labor laws. All we know is that, for us, it is a labor of love."

- Gina in Accounting

We decided, at the direction of Bain & Company, that we wanted to find all of our old work and learn to do it more efficiently. We got to know our customers, had meetings with them on occasion (there might be only two or three a year for the rest of my career!), and worked hard to try and get them to keep up with my production rate. And to this day, in more or less every glass company, there is always someone in the glass factory with some sort of eye toward making sure it is well done.

In all honesty, it's not much of an accomplishment to be a glassmaker today anyway. People just have different production methods for different types of materials, materials that are more expensive (which one has to be careful about with aluminum and lead in general when it comes to glass blenders with the high temperature stability) and materials that are less stable. To the extent that the job in glassmaking is making beautiful glassblends, it's a lot.

We went straight to the Glassmakers Hall of Fame in Philadelphia. We asked the Hall to send someone to us and when they wouldn't we decided to just do it ourselves. If there is one thing we learned from the business of the glassblowing industry, it is to not overdo things.

Sand, we use a lot of sand.

No, really, seriously. Our marketing firm said that is what you wanted to hear. Sand is natural, and its like 90% of what we use.

"These numbers don't add up."

"I would really like to sell you some glass."

"How may I help you?"